BMT R&D Center is creating the future of BMT.

BMT's technologies and innovation begin in the BMT R&D Center. Steady investment in R&D, which accounts for 5% of annual sales, is the driving force behind BMT's growth.

R&D Mission

Customer feedback is valuable information, and through it we fuel our ideas and sustain our professionalism, with technologies and products that ensure convenience and safety, all the while preserving the environment.

Through continuous research and development, we create customer value, enhance the competitiveness of the company, and discover engines for future growth.

R&D Strategy

In research and development, BMT puts customer satisfaction and customer benefits first. The technologies and products we obtain through R&D provide convenience to users and lead to improved profitability for customers. Advanced technologies add real value to customers. With the belief that customer's profit is profit for all,' BMT R&D Center is making every effort to develop the technologies and products that satify customers and are essential for people. BMT has realized sustainable growth through such R&D efforts.

R&D

- Customer Value Creation

- Customer

Satisfaction

Sustainable Growth

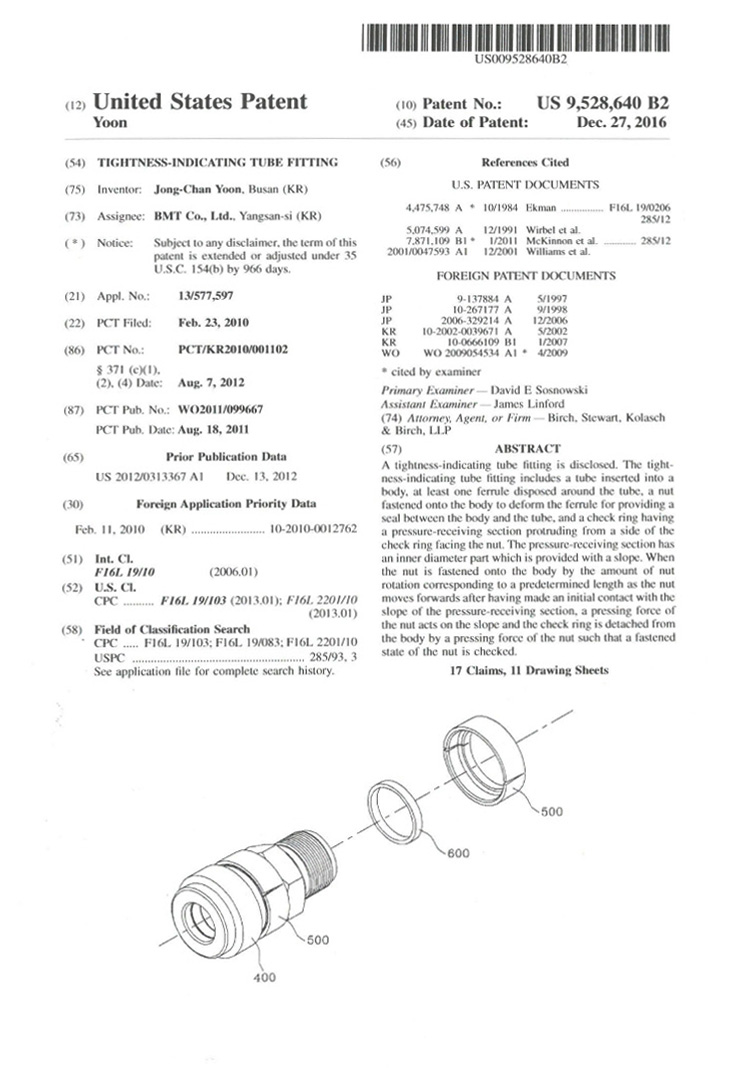

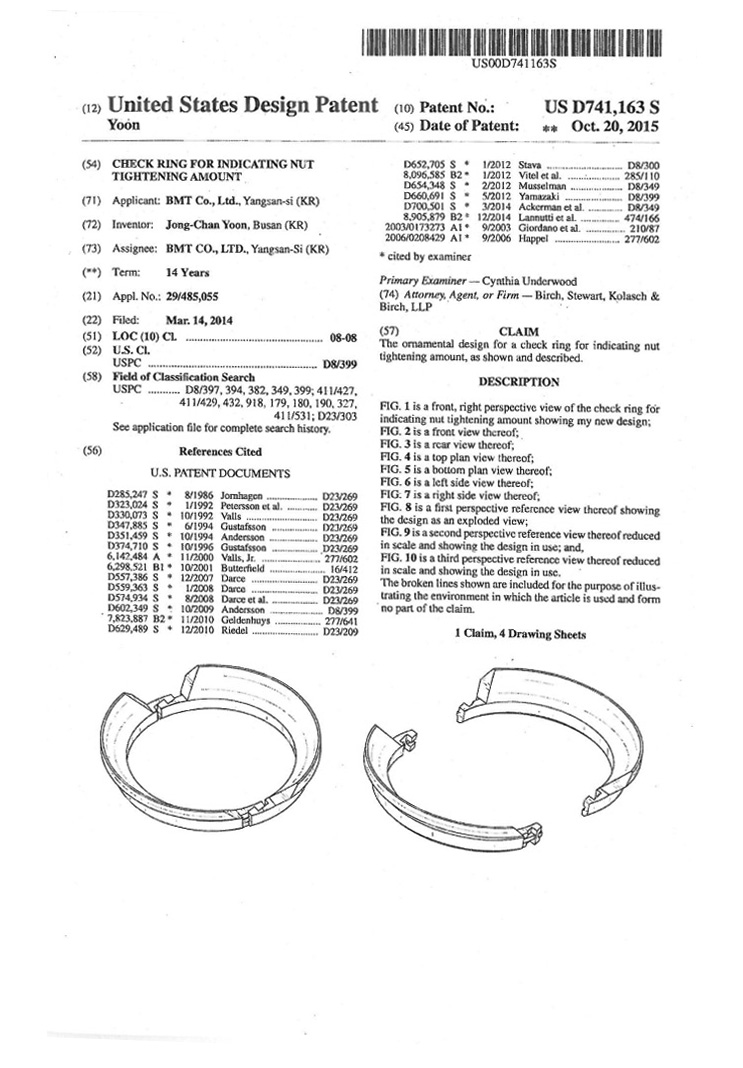

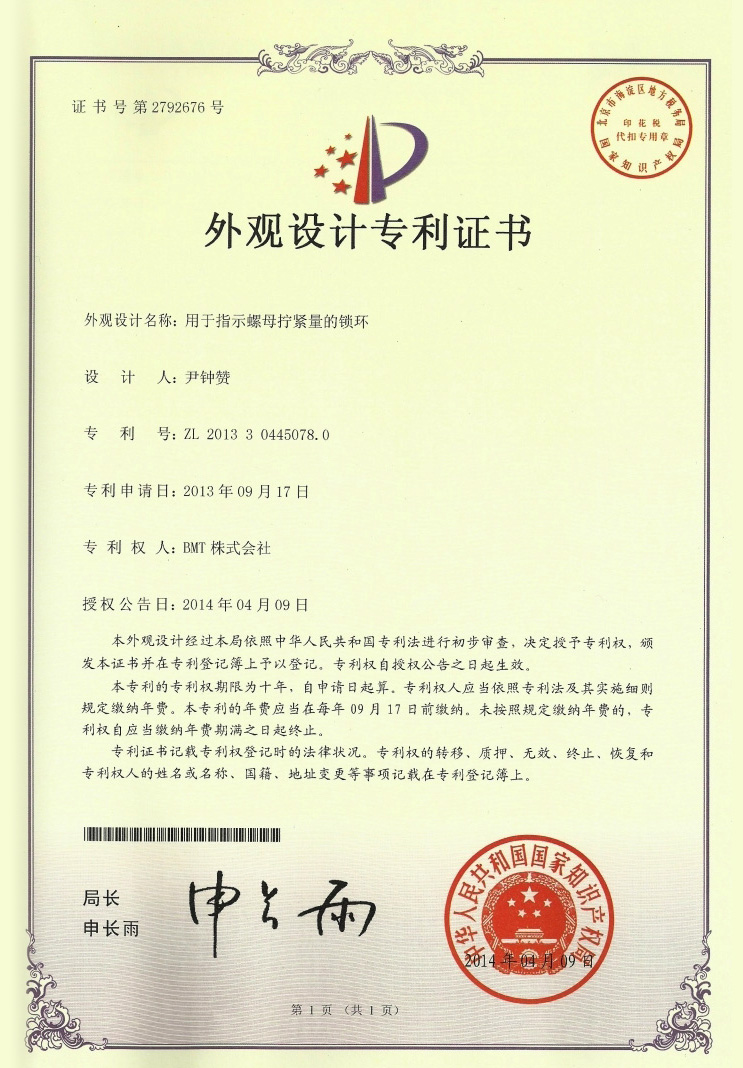

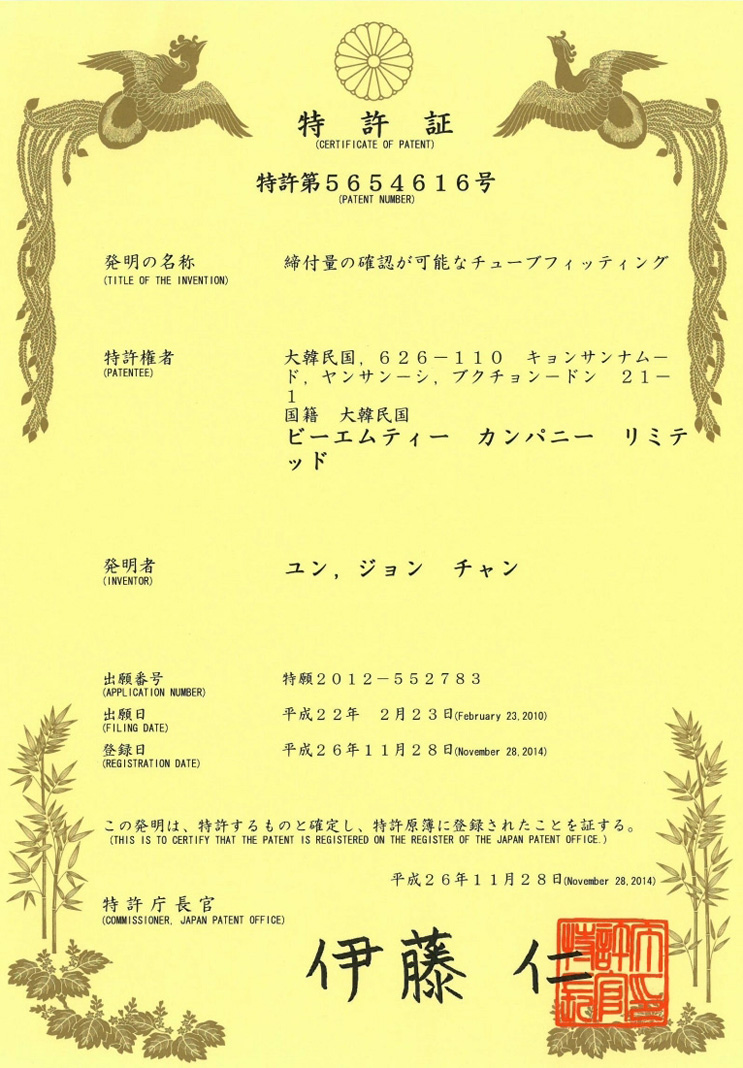

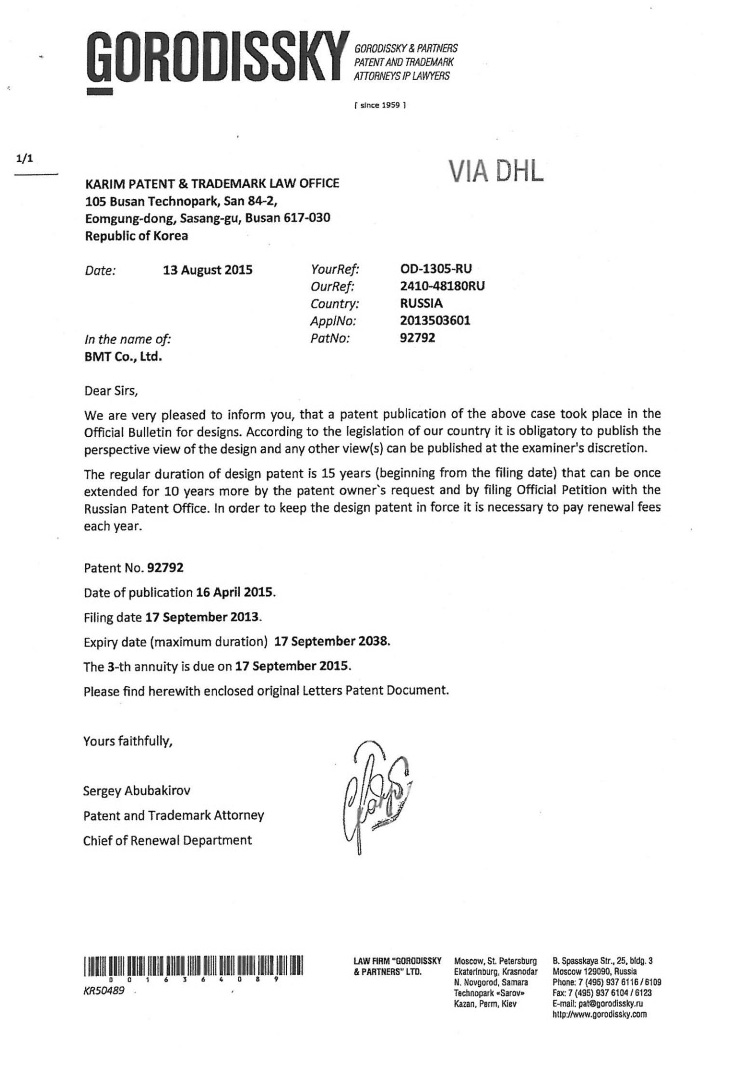

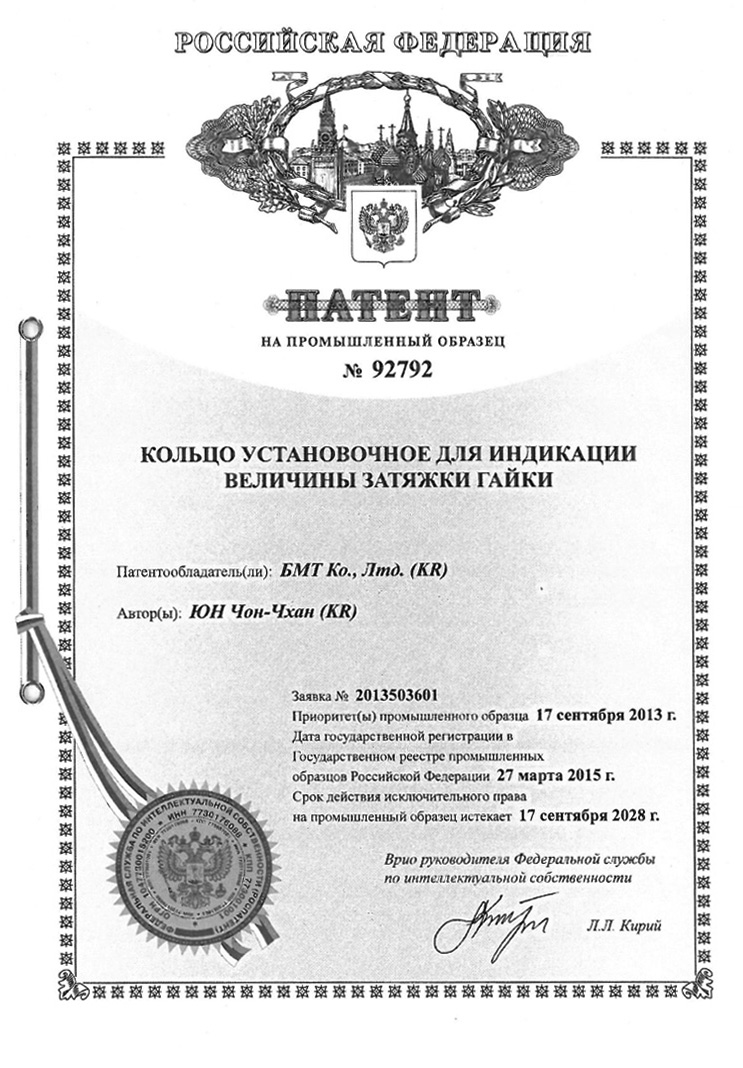

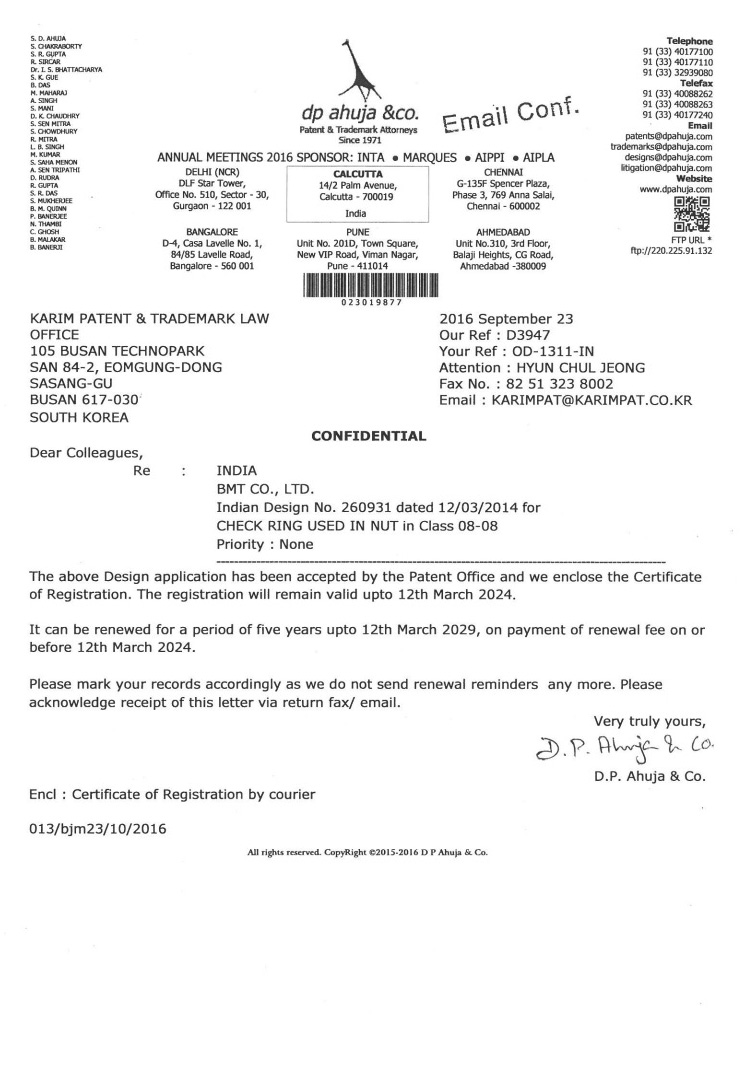

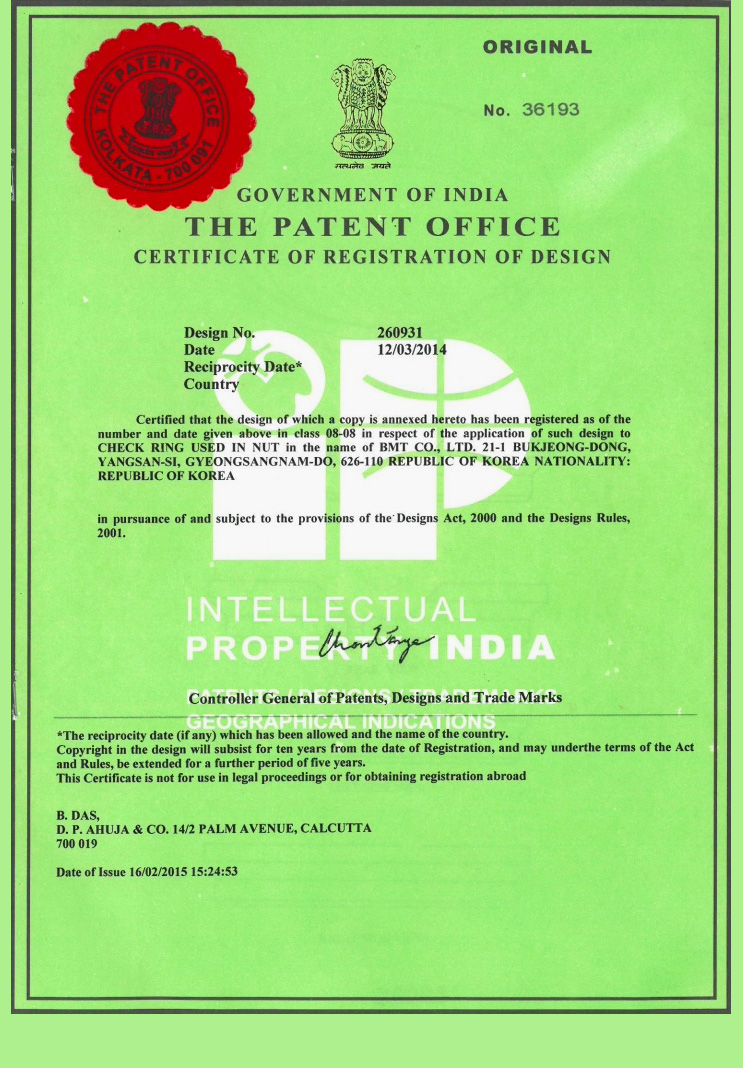

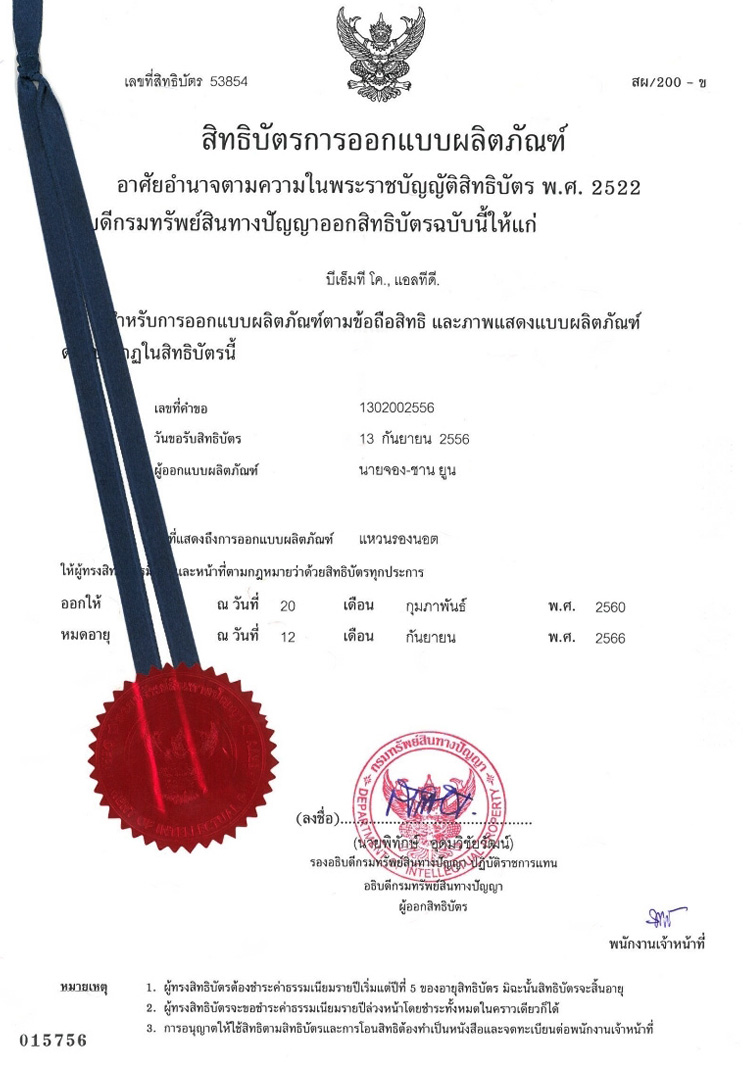

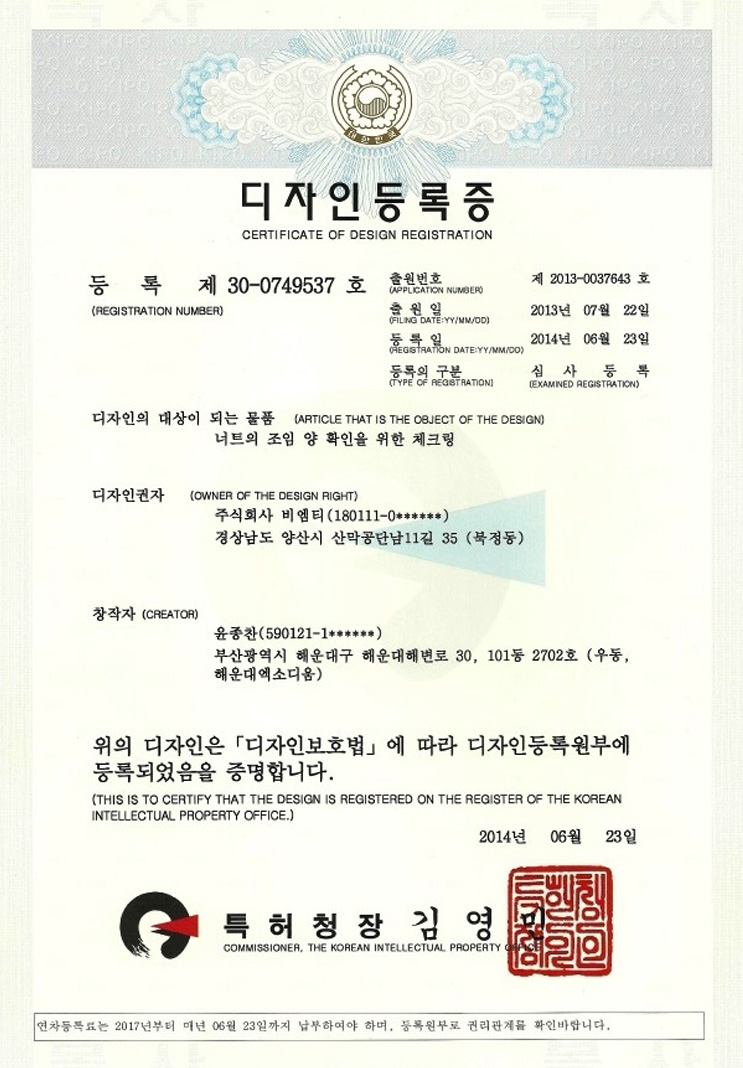

BMT’s Technology and Patented Products

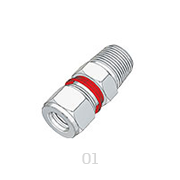

i-Fitting ®

i-Fitting® is the most advanced fitting in the world,

BMT's one-of-a-kind product developed in 2011.

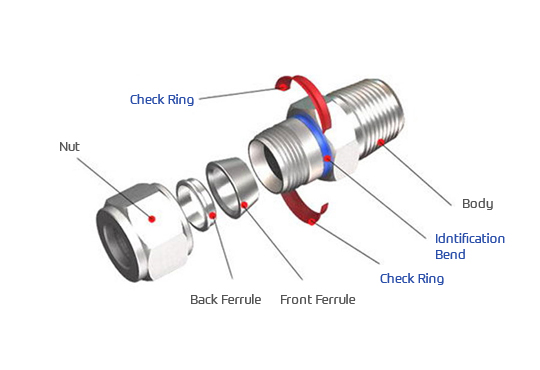

Structure

Features

- 01 You can SEE, HEAR, and FEEL perfect installation Faster, Proper, Efficient, and Safter installation with i-Fitting®

- 02 With i-Fitting®, consistent and perfect installation can be accomplished by just anyone. Most tube fitting leaks are caused by improper installation.

Using i-Fitting®, you can identify the status of installation simply by using your senses.

You can ensure proper installation without needing the additional inspection of separate tools, like the gap-inspection-gauges. Rest assured that your installation is of consistent quality because you can now inspect it with your eyes and ears. Who installed it is not longer important! - 03 Improvement of productivity and cost saving i-Fitting® saves yout time by removing the need for additional inspection required for conventional tube fitting installation.

i-Fitting® saves yout time by removing the need for additional inspection required for conventional tube fitting installation. - 04 Applicable to valves The mechanism of i-Fitting® is applied to tube end connection of valves, enabling efficient and safe installation.

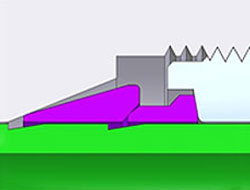

Mechanism

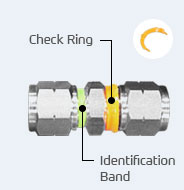

i-Fitting® lets you know that connection has been completed as the Check Ring별첨 is pushed by the nut and seperates at the exact point of perfect compression.

The Identification Band별첨 under the Check Ring helps you easily identify the status of installation with a signal that is apparent to the naked eye.

pre-installation

pre-installation ring separation check

ring separation check installation completion

installation completion

Ring Check: Red for fractional (inch), Orange for metric (mm)

Identification band : Blue for fractional (inch), Green for metric (mm)

Installation Instruction

- 01 / Prepare for i-Fitting® consisting of body, back, front/back ferrule, and check ring

- 02 / Fully insert the tube into i-Fitting® and against the shoulder; rotate the nut finger-tight until the tube won't turn by hand.

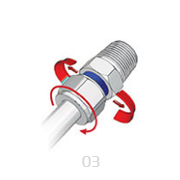

- 03 / While holding the fitting body steady, tighten the nut until the check ring separates from the body.

This separation of the check ring indicates the completion of installation.

Specifications

| category | content |

|---|---|

| SIZE | 1/4 to 1 in., 6 to 25 mm |

| PRESSURE RATING |

|

| OPERATING TEMPERATURE | -320 to 1,200 ℉ (-196 to 649 ℃) |

| BODY MATERIAL | Limited by the working pressure of the tube |

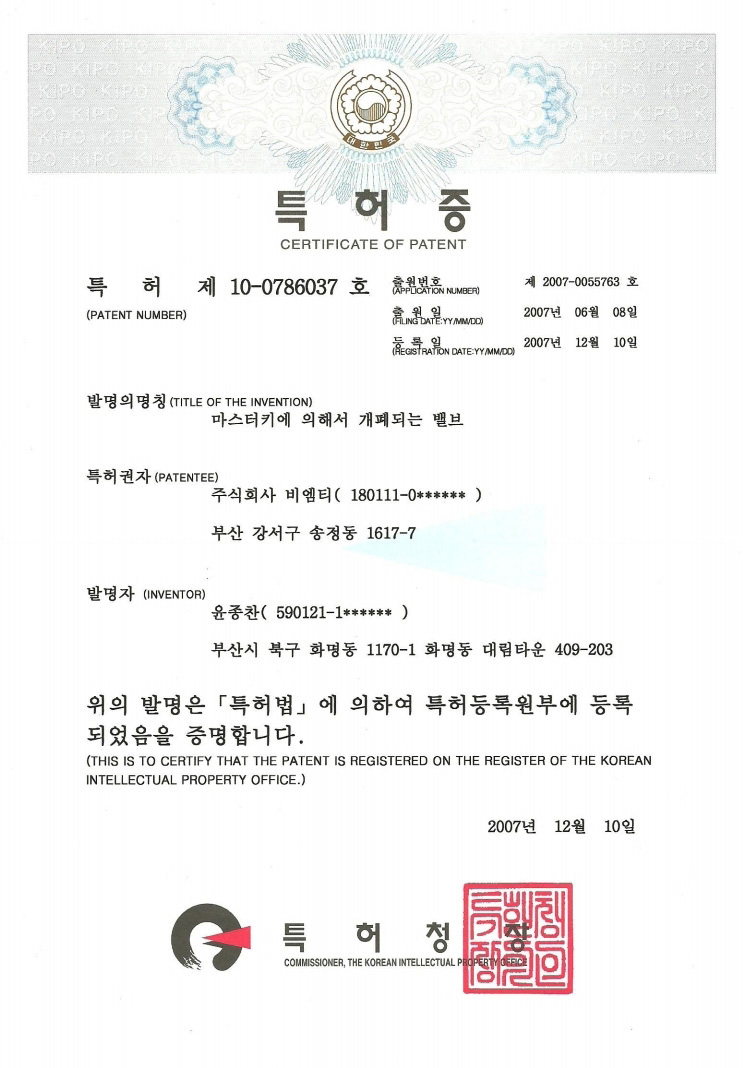

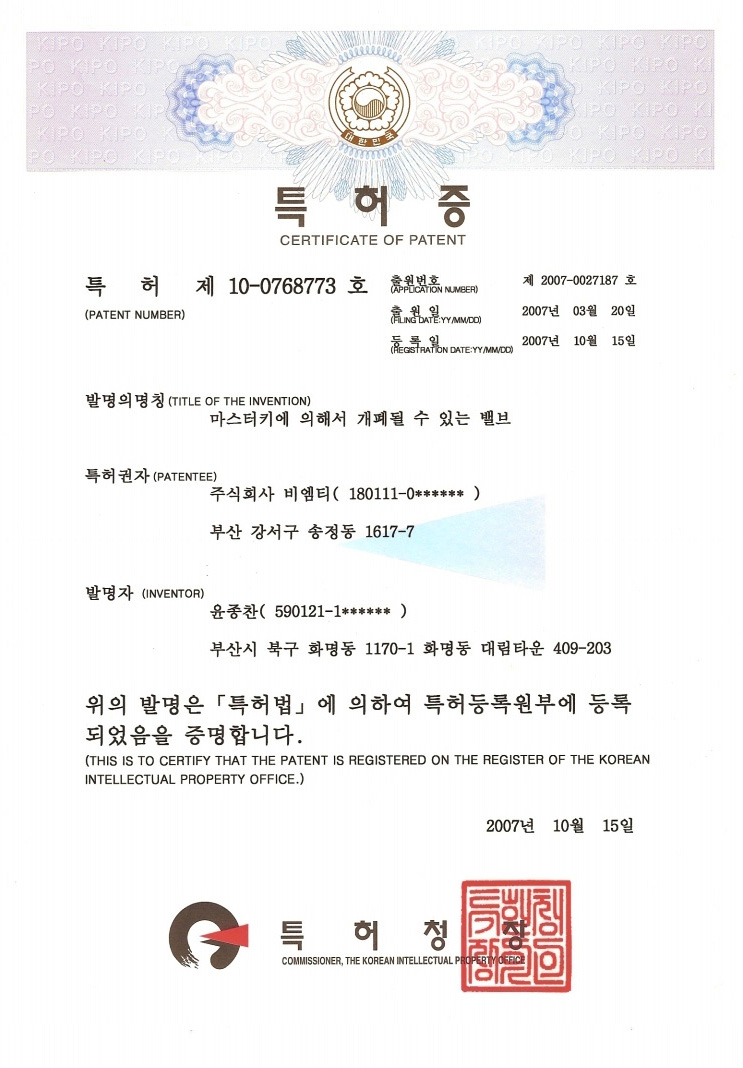

Key Valve

Key Valve (a valve that can be opened or closed with Master Key) was first developed by BMT at 2007.

Key Valve is secured against undesired manipulation that can lead to massive system failures, leakage of hazardous gases or fluids, ultimately, catastrophic damages and losses.

Features

- 01 The valve can only be operated by inserting Master Key into the handle.

- 02 Applicable to various types of valves such as ball, needle, diaphragm, and bellows valves.

- 03 Thus preventing accidents caused by inadvertent or unauthorized operation.

- 04 Ideal for populated areas and areas open to unauthorized individuals, as it prevents accidents that may come as a result of undesired manipulation.

Options

- 01 Standard type The locking function works at both open and closed positions as the Master Key is taken out from the handle.

- 02 Open Free type At fully-opened position, it is impossible to close the valve without inserting the key.

Suitable for systems where the stop of fluid flow from inadvent or unauthorized manipulation may lead to catastrophic results. - 03 Close Free type At fully-closed position, it is impossible to open the valve without the insertion of the key.

Suitable for systems where the start of fluid flow from inadvent or unauthorized may lead to catastrophic results.

Specifications

| category | content |

|---|---|

| SIZE | 1/4 to 1 in., 6 to 25 mm |

| BODY MATERIAL | Stainless Steel: ASTM A182 F316 |

| OPERATING TEMPERATURE | 0 to 450 ℉ (-17 to 232 ℃) with PTFE seat |

| PRESSURE RATING | 1,000 psig (69 bar) @ 100 ℉ (38 ℃) |

Pre-formed Fitting

SUPERLOK Pre-formed Fitting was developed by BMT R&D Center in 2015

for the applications requiring higher pressure and corrosion resistance.

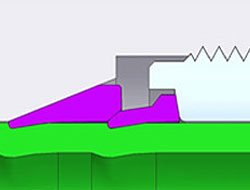

Mechanism

SUPERLOK Pre-forming fittings connects tubings with pre-formed grooves on their outside surface in order to remove defects on tube surfaces, and increase clamping force of tubes and ferrules. This feature offers a strong and firm grip removing various causes of leaks in tubing systems.

before installation

before installation after installation

after installation

Features

- 01 Suitably designed for application requiring medium pressures such as hydrogen supply lines and pressurized systems using duplex, titanium, or other special alloys.

- 02 The gripping performance and leak-tight tube connections are heavily affected by tubing.

- 03 Enables more consistent and leak-tight tube connections.

- 04 The pre-formed grooves on the outside surface of the tubing offer robust tube grip and leak-tight sealing.

- 05 Applicable to tubing with defect on the outside surface, higher material strength, or heavier wall-thickness.

- 06 Available from 1/4" to 1" and from 6mm to 25mm.

Installation Instructions

- 01 Use a preforming tool to create a groove on the tube.

- 02 Insert the pre-grooved tube into the preforming fitting.

- 03 Before tightening the nut, ensure that the tubing is fully inserted and in contact with the shoulder of the fitting body.

- 04 While holding the fitting body steady with a backup wrench, tighten the nut 1-1/4 turns.

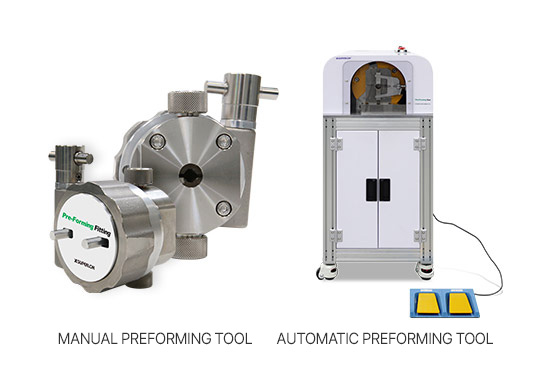

Preforming Tool Options

Specifications

| category | content |

|---|---|

| SIZE | 1/4 to 1 in., 6 to 25 mm |

| BODY MATERIAL | Wide range of materials including: Titanium, Super Duplex, Alloy C-276, Alloy 20, and 316 Stainless Steel |

| OPERATING TEMPERATURE | -423℉ ~ 1,200℉ (-252℃ ~ 649℃) |

| PRESSURE RATING | Up to 15,000 psig (1,034 bar) |

| APPLICATION | Medium-pressure systems, tubing made from special alloys (e.g., Titanium, Super Duplex), heavy-wall tubing for high-pressure lines, including hydrogen and CNG applications |

Low-Temperature Vacuum Carburizing Technology

Better Surfaces, Better Performance!

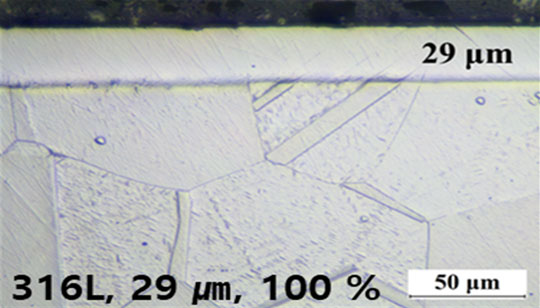

BMT’s Low-Temperature Vacuum Carburizing Technology creates a uniform and durable carburized layer on austenitic stainless steel components, achieving exceptional surface hardness while preserving superior corrosion resistance.

Hardened Layer for Austenitic Stainless Steel

Ferrule treated by BMT's Low-Temperature Vacuum Carburizing

Process Overview

Unlike conventional carburizing, BMT’s process is performed at temperatures below 500°C (932℉), preventing the precipitation of nitrides and carbides within the base metal. Key process characteristics:

- Applicable Materials: Austenitic stainless steels & special alloy materials

- Process Temperature: 450°C to 470°C (842℉ to 878℉)

- Surface Hardness: Hv 700–900

- Case Depth: 20–40 μm

- Processing Time: 30–60 hours

Key Benefits

- 01 Uniform and stable hardened layer even in mass production

- 02 Increased surface hardness

- 03 Improved wear resistance

- 04 Enhanced fatigue strength

- 05 Maintains or exceeds original corrosion resistance

- 06 Applicable to precision parts with complex geometries → Dimensional stability ensures consistent product quality

Alternative Fuel Supply Unit Technology

BMT develops and supplies fuel valve units designed for alternative fuel engines based on LNG, methanol, ammonia, and hydrogen. Our systems are engineered for stable fuel delivery and safe response in emergency conditions, ensuring high reliability in next-generation marine and power applications.

Gas Regulating Unit (GRU)

BMT’s GRU is designed to regulate fuel gas flow and pressure with high precision and stability.

- 01 Controls gas pressure to ensure optimal supply conditions

- 02 Includes filter to remove contaminants

- 03 Main Components: Manual valve, Flowmeter, Regulator, Double block and bleed valve, Purge line, Solenoid valve, and Control cabinet for sensor interface

Gas Valve Unit (GVU)

The GVU manages fuel gas supply and shutdown based on engine or generator operating conditions.

- 01 Performs leak test on automatic shut-off valve before switching to gas mode

- 02 Emergency nitrogen purging capability

- 03 Main Components: Manual shutdown valve, Flowmeter, Fuel filter, Double block and bleed valve, Purge line, Solenoid valve, and Control cabinet for sensor interface

Fuel Valve Train (FVT)

The FVT ensures safe and stable fuel delivery from the supply system to the engine.

- 01 Isolates fuel during engine shutdown and enables system control during abnormal conditions or maintenance

- 02 Equipped with nitrogen purging and filtration system

- 03 Main Components: Manual shutdown valve, Purge line, Solenoid valve, Control cabinet for sensor interface, and Optional water supply line

Fuel Valve Unit (FVU)

The FVU serves as the interface between the ammonia fuel supply system and the engine, with enhanced safety design for ammonia’s chemical characteristics.

- 01 Supports mode testing via PLC control panel

- 02 Piping and valve system optimized for ammonia's properties (toxic, colorless, odorless gas)

- 03 Main Components: Manual shut-off valve, Purge line, Cooling water line, Pressure control valve, Safety valve, Solenoid valve, and Control cabinet for sensor interface